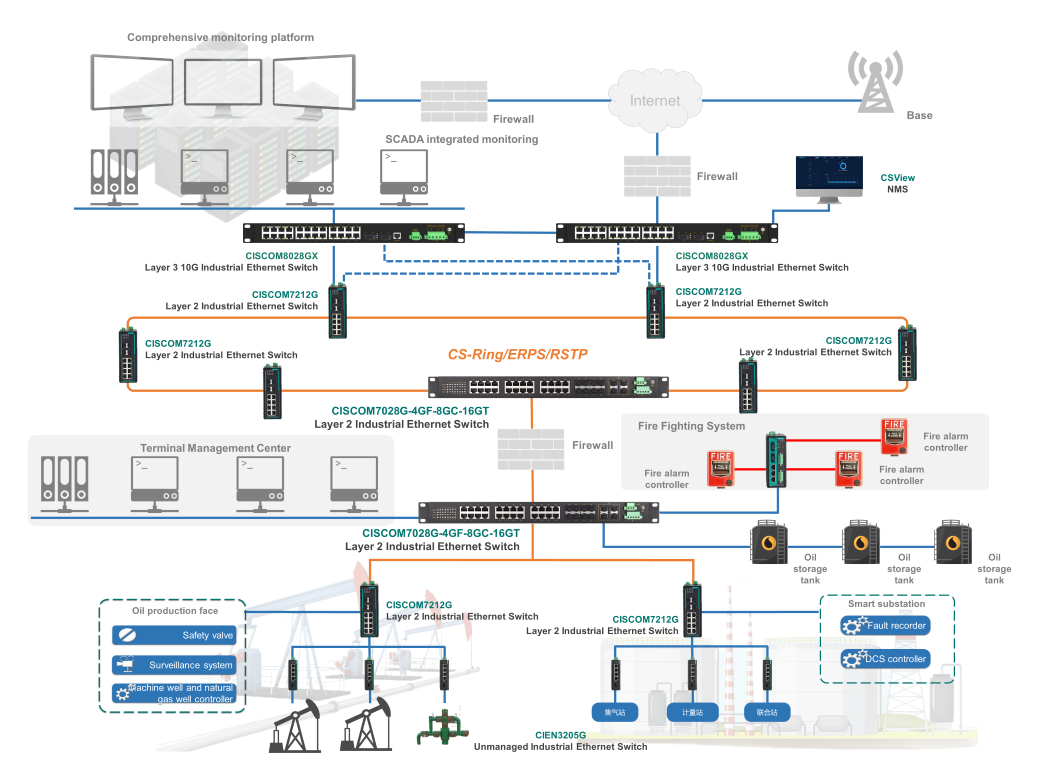

System Overview

The construction of intelligent digital oil and gas fields needs to build a safe, efficient and reliable automation network to improve oilfield production, strengthen production process control, and assist production management. Through the wired optical fiber transmission network and wireless transmission network, the production data and equipment status information between oil and gas field wells, metering rooms, integrated stations, joint stations, and processing plants are realized in real time.

COME-STAR Solution

System requirement:

1) The communication network meets industrial design standards and can achieve safe, reliable, and stable operation in a harsh environment;

2) High -bandwidth backbone network, which can transmit large -flow IP data such as video, audio and business data at the same time;

3) Support the redundant self -healing function, it can be recovered quickly when the network fails;

4) Security networks, protecting monitoring is not affected by malicious attacks;

5) With strong network management capabilities, support fast network failure diagnosis, and ensure the smooth operation of the system.

Solution:

Different systems in the mining of Oil and Gas Fields deploy different network switches equipment in different systems, collecting oil collection working noodles and downstream equipment data of smart substation through CISCOM7212G, CIEN3205G switch equipment, and finally collected all data to the main ring network. The method of ringwriting composed of industrial Ethernet switches and the monitoring center of the monitoring center build a multi -ring topology structure, and the product meets the stable and reliable application needs under the level 4 of the industrial level 4. The network has the characteristics of real-time collection function, scalability, high reliability, high bandwidth, high-quality network signal transmission and redundant backup.

Recommended Products