System Overview

The DCS system is aimed at various manufacturing industries. Because each industry has its own particularities, the DCS system also has different branches. This is caused by the limitations of the production and manufacturing processes of different industries by the manufacturer's technical designers (such as the petrochemical industry and the electric power industry). DCS is applied to power plants. Like the general DCS system, it controls various execution components according to the power plant's operating logic based on various simulation data volumes. This is a comprehensive system that can not only accurately collect various data and correctly issue control instructions when basic functions, but the key is to analyze and judge various data, which is the key to improving the efficiency of power plants.

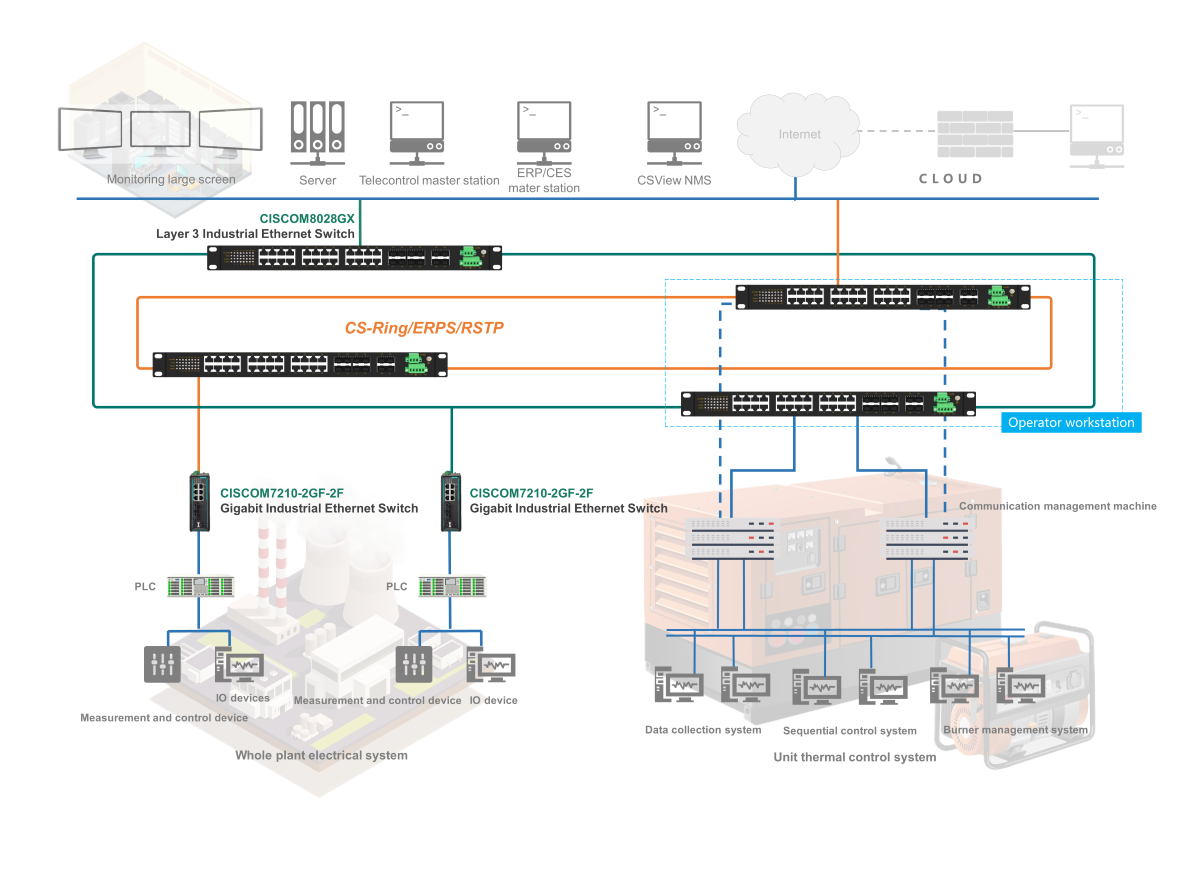

COME-STAR Solution

System requirement:

1) Networking supports star, ring, and bus topologies;

2) Compatible with various fieldbuses, such as HART, ProfiBUS-DP/PA, ModBUS, etc.;

3) Fully redundant configuration (system network, control network, controller, power supply, IO module);

4) Multiple isolations (for photoelectric isolation between bus network and modules, power supply isolation);

5) Multiple protections, including electrostatic discharge immunity, radio frequency electromagnetic field radiation immunity, surge shock, electrical fast transient pulse group, radio frequency field induced conducted disturbance immunity, voltage sag and short-time interruption immunity, etc.

Solution:

COME-STAR adopts a multi-ring coupling structure. The single ring composed of CISCOM7210G-2GF-2F industrial Ethernet switches at each furnace site is coupled with the ring of the monitoring center to form a multi-ring coupling topology. The network has the characteristics of real-time acquisition function, scalability, high reliability, high bandwidth, high-quality network signal transmission and redundant backup. With this networking method, each furnace not only achieves redundancy on site, but also achieves redundancy in communication with the monitoring center. In addition, since each furnace itself is linked to the monitoring center in a coupling ring manner, this ensures that the monitoring between the furnaces does not affect each other. The on-site controller realizes redundant backup through the single ring on site, and redundant dual backup is also adopted in the monitoring center, which makes the entire network have a high degree of redundancy and the stability of the network is particularly high.

Recommended Products